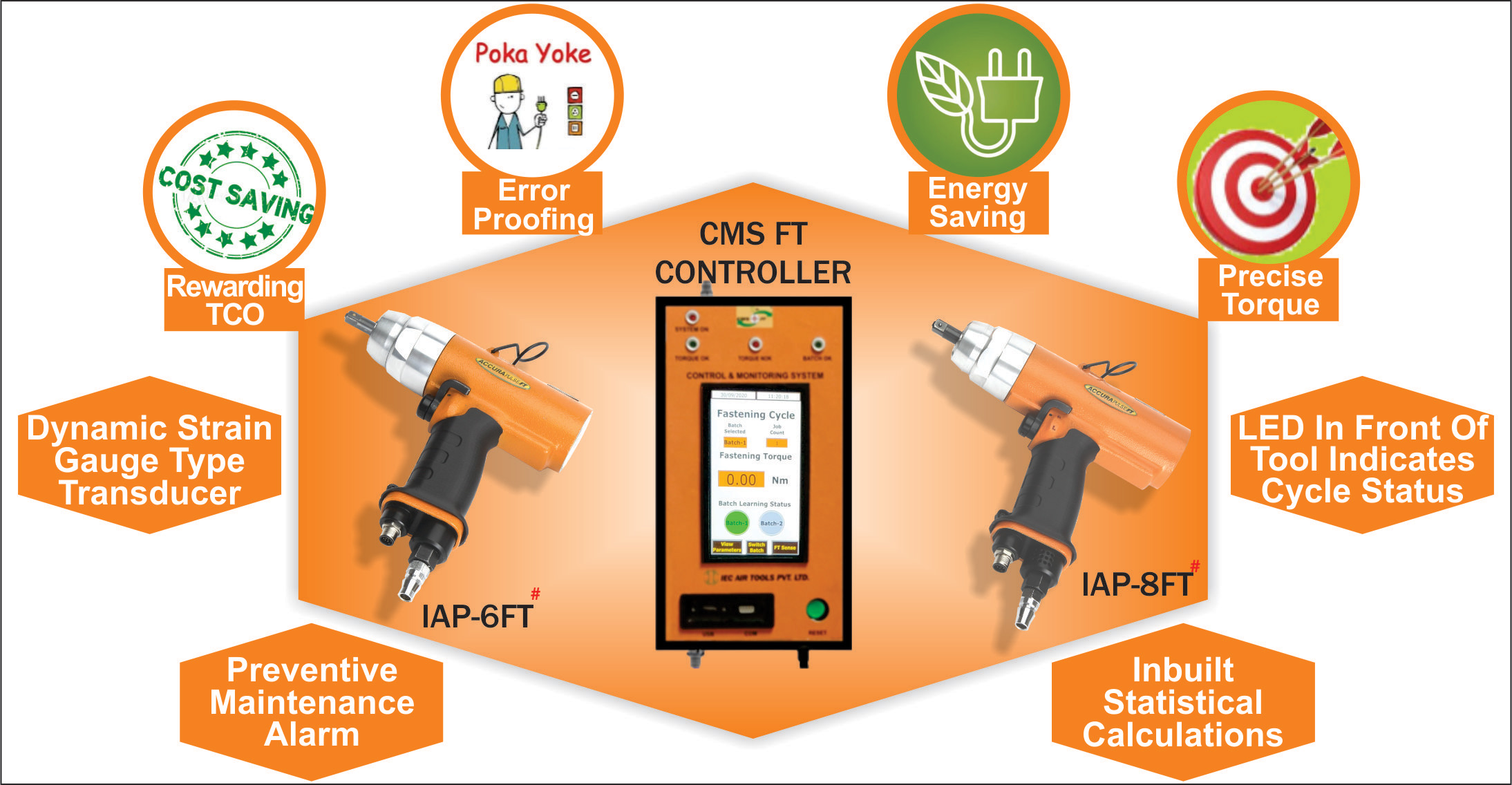

Accura FT Series Transducerised Pulse Tools and Acura CMS FT – V2 Controller

Meeting market needs

Most manufacturing operations today cater to a high demand market, and quick turnaround is the differentiator between competitors.

However, speed does not mean a compromise on accuracy.

Do your industrial machine tools meet your exact specifications? Give your manufacturing operation the dual benefit of speed and accuracy.

Your bottom-line matters

Fast and accurate tightening has the power to increase efficiency and productivity for any manufacturing operation. You can meet demands without compromising on the quality of your product. Simply by choosing between pneumatic vs electric power tools, and vastly improve your fastening process.

IEC fastening offering

IEC Air Tools is your fastening partner for all your needs. The Accura FT series of Transducerised pulse tools in combination with the CMS FT – V2 Controller will make the tightening process seemingly effortless.

Besides speed, efficiency and an increase in productivity, these transducerised pulse tools offer you:

-High accuracy

-Stability

-Ease of use

-Consistent torque

-Better control

-Simple initial engagement

-Easy maintenance

-Minimal wear and tear

Salient Features of Accura FT Series

Transducerised Pulse Tools

Integrated rotary strain gauge type transducer with high accuracy 0.5% of full scale

The accura pulse FT tools are unique and are registered design

Multicolor LEDs mounted in front of the tool indicating work progress

& Cycle OK/NOK status easily visible to the operator a Unique Feature, no need to check at

controller end

Complete fastening process control

Easy initial engagement of fastener

Powerful Double Chamber Air Motor

Double Blade Pulsing Mechanism

Durable Performance

Fast and Accurate tightening

Increased MTBF

Wear and Tear of the tool is minimised as excessive running of the tool is

controlled

Zero torque reaction on shut off. This eliminates the need of reaction arm

and related expensive accessories

Saves compressed air energy

Low Noise and Lesser Vibrations

Reduction in operator fatigue

Modular design ensures Easy Maintenance

All major parts of the tool are from the proven Accura Pulse Series tools

which translates to

TC + TV = FT

Specifications

Model | Capacity Bolt Size | Free | Torque Adjustment Range | Square Drive Shank | Weight | Overall Length | Air Inlet Thread | Air Hose Size | Air Pressure | |

MM | RPM | (N-m) | MM | Kg | MM | BSP | MM | Kg/Cm2 | ||

Min | Max | |||||||||

IAP-6FT # | M8 | 7000 | 15 | 35 | 9.5 | 1.65 | 197.5 | 1/4” | 9.5 | 6.0 |

| IAP-6FTD | M8 | 7000 | 15 | 25 | 6.35* | 1.65 | 200.5 | 1/4” | 9.5 | 6.0 |

| IAP-8FT # | M8-M10 | 6000 | 35 | 70 | 9.5 | 1.75 | 219.5 | 1/4” | 9.5 | 6.0 |

# Registered Design

*Anvil Drive HEX

Salient features of FT (Fastening Torque)

Series Controller – CMS (FT)

Models Available

B4 : Four batches with same torque settings

BT-2 : Two batches with different torque settings

Large 7″ capacitive, multicolour touch screen

interface displaying fastening torque & cycle status OK/NOK

- Contemporary Compact Vertical Design.

- Improved Accuracy

- Features Rich Error Proofing

- Batch Switching Features

* Provision to skip batch – 2

learning, after completing Batch – 1 learning.* Master reset, to erase all learnt data for

Batch 1 & 2.* Direct toggle between Batches.

- Added FT Features

Closed-loop torque control & torque validation (Date & Time

stamped) when used with FT Series TransducerisedAccura Pulse Tools

Precise Torque Control & Multiple parameter Set Capability

Storage Capacity of 10000 Fastening cycles in internal memory and 2/8/16GB

USB compatible for taking rundowns backup more than 50,000 readings can be stored.

Error proofing of Process

Cycle OK/NOK

Batch OK/NOK

Early and mid-trigger release

Re-hit

Transducer cable fault

Preventive Maintenance Alarm

Extra 2 Outputs (Batch OK & Cycle NOK) that can be integrated with

your line for further process control

Free run NOK

Cross Thread Detection

As process is controlled and monitored, tools operate with better accuracy

Simultaneous rundown recording via Ethernet

Provision to interface printer / scanner with FT controller on customer

demand

Energy saving as tool shuts off on reaching desired fastening torque with

accuracy and control. Free running of tool or excessive running of the tool is totally avoided as the controller

declares NOK and raises alarm

TCO : CMS FTsystem offers great value and services. Life cycle of the

product and total cost of ownership is rewarding as the cost of components and electronics is competitive as

compared to other options available in the industry.