Accura Oil Pulse Wrenches

The ideal fastening tool for modern assembly lines, our combination tool, which consists of an air motor and a unique hydraulic pulse unit, offers distinct advantages over conventional Impact Wrenches and Nut-runners. It is designed to provide better quality fastening, longer tool life, and enhanced operator comfort.

When selecting Pulse Tools for your assembly line, it is important to check the joint conditions. Optimum results can be achieved by using the tool at its rated working pressure. It is recommended to choose the most suitable model for your specific requirements.

To ensure proper operation, use the correct size of hoses and couplers and Impact Sockets. Additionally, maintaining clean and dry air will further enhance the life of the Pulse Tools.

- IAP-3

- IAP-6

- IAP-8M

- IAP-8MSA

- IAP-8

- IAP-8S

- IAP-10

- IAP-16

- IAP-18

- IAP-20

- IAP-24

Salient Feature

Powerful Double Chamber Air motor

The double chamber air motor delivers higher torque than conventional single chamber air motor. This offers higher

power to weight ratio leading to superior and economic performance.

Fast and Accurate tightening

Accuracy is crucial, in case of hard and soft joints, the same are tightened accurately. Thus providing high product

quality on your lines. Since the Accura Pulse Tools have a wide torque range, each tool can be adjusted for many

applications.

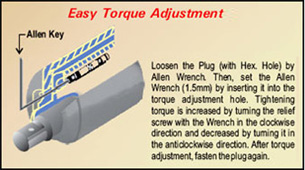

Ease of Torque Adjustment

Torque can be easily set by Allen key without dismantling the tool.

Double Blade Pulsing Mechanism

The torque generated by double blade pulse unit mechanism is well balanced and higher torque is attained than single

blade mechanism.

Durable Performance

Torque is generated by hydraulic pulse unit wherein there is no metal to metal impacting as in case of Impact

Wrenches. This reduces breakdowns and gives longer life.

Low Noise and Lesser Vibrations

The hydraulic pulse mechanism and silencer reduces noise, vibrations and eliminates reaction. This improves operating

comfort by reducing operator fatigue.

Ease of Operation

Initial engagement of fastener is easier because of provision of throttle adjustment for low speed starting.

Rubber Grip

Provides comfortable grip and vibrations are reduced.

Model | Capacity Bolt Size | Free Speed | Torque Adjustment Range (N-m) | Square Drive Shank | Weight | Overall Length | Air Inlet Thread | Air Hose Size | Air Pressure | |

MM | RPM | Min | Max | MM | Kg | MM | BSP | MM | Kg/Cm2 | |

IAP-3 | M5 | 7500 | 9 | 15 | 9.50 | 0.81 | 139.00 | 1/4″ | 9.5 | 6.0 |

IAP-3D | M5 | 7500 | 8 | 13 | 6.35** | 0.82 | 147.50 | 1/4″ | 9.5 | 6.0 |

IAP-4S | M5 | 8000 | 9 | 15 | 9.50 | 0.95 | 220.00 | 1/4″ | 9.5 | 6.0 |

IAP-4SD | M5 | 8000 | 8 | 13 | 6.35** | 0.96 | 225.00 | 1/4″ | 9.5 | 6.0 |

IAP-6 | M6-M8 | 6500 | 25 | 35 | 9.5 | 0.95 | 155 | 1/4″ | 9.5 | 6.0 |

IAP-8M | M8 | 7000 | 15 | 35 | 9.50 | 1.19 | 146.00 | 1/4″ | 9.5 | 6.0 |

IAP-8MD | M8 | 7000 | 15 | 30 | 6.35** | 1.19 | 151.00 | 1/4″ | 9.5 | 6.0 |

IAP-8MS | M8 | 8200 | 15 | 35 | 9.50 | 1.20 | 221.00 | 1/4″ | 9.5 | 6.0 |

IAP-8MSD | M8 | 8200 | 15 | 30 | 6.35** | 1.20 | 226.00 | 1/4″ | 9.5 | 6.0 |

IAP-8MSA * | M8 | 7000 | 15 | 35 | 9.50 | 1.64 | 256.00 | 1/4″ | 9.5 | 6.0 |

IAP-8 | M8-M10 | 6000 | 35 | 70 | 9.50 | 1.30 | 168.00 | 1/4″ | 9.5 | 6.0 |

IAP-8D | M8-M10 | 6000 | 30 | 60 | 6.35** | 1.30 | 171.00 | 1/4″ | 9.5 | 6.0 |

IAP-8S | M8-M10 | 6500 | 35 | 70 | 9.50 | 1.25 | 245.00 | 1/4″ | 9.5 | 6.0 |

IAP-8SD | M8-M10 | 6500 | 30 | 60 | 6.35** | 1.25 | 250.00 | 1/4″ | 9.5 | 6.0 |

IAP-8SA* | M8-M10 | 5500 | 30 | 60 | 9.50 | 1.80 | 292.00 | 1/4″ | 9.5 | 6.0 |

IAP-10 | M12 | 5800 | 70 | 120 | 12.70 | 2.04 | 196.00 | 1/4″ | 9.5 | 6.0 |

IAP-16 | M16 | 2800 | 120 | 200 | 12.70 | 3.65 | 210.00 | 1/4″ | 9.5 | 6.0 |

IAP-18 | M18 | 2400 | 200 | 300 | 19.05 | 4.90 | 240.00 | 3/8″ | 12.7 | 6.0 |

IAP-20 | M18-M20 | 4000 | 300 | 400 | 19.05 | 6.50 | 270.00 | 3/8″ | 12.7 | 6.0 |

IAP-24 | M24 | 3500 | 300 | 550 | 25.40 | 12.50 | 443.0 | 3/4″ | 12.7 | 6.0 |

Note

*Angular

** Tool Specifications to be read as Anvil Drive Hex. (Q.C.)

# Torque and RPM ratings available @ 5Kg/Cm2

- Check joint conditions while selecting Pulse Tools.

- Rated working pressure will give optimum results.

- Select most suitable model.

- Use correct size of Hoses and Couplers.

- Use Impact Sockets only.

- Clean Dry Air will further enhance the life of Pulse Tools.